世界のキャンディ市場の急成長に伴い、グミキャンディはその楽しさ、豊かな味わい、柔軟な成形性により、人気のあるスナックカテゴリーとなっている。製品ラインを迅速に拡大し、生産コストを削減し、多様なフレーバー、楽しい形状、パーソナライズされたパッケージングに対する消費者の需要に応えるために、受託製造に注目する小売業者、ブランドオーナー、輸入業者がますます増えている。

グミキャンディの受託製造とは?適切な受託製造業者を選ぶには?この記事では、企業が十分な情報に基づいた意思決定を行うための包括的な説明を提供します。

グミキャンディの受託製造とは?

OEMとも呼ばれるグミキャンディ受託製造とは、ブランドオーナーがグミキャンディの研究開発、製造、パッケージング、物流工程の一部をこの分野に特化した工場に委託し、顧客の要望に応じて製造工程全体を仕上げることを意味する。グミ・キャンディの受託製造には、従来の自社工場と比較していくつかの利点がある:

- コストと資源の節約: 工場を建設したり生産設備を購入したりする必要がないため、投資と労働の固定費を大幅に削減できる。

- 市場投入までの時間を短縮: 既存の工場はすでに最先端の生産設備と経験豊富な技術者を擁しており、大量注文への迅速な対応が可能である。

- カスタマイズの柔軟性: グミキャンディの味、色、形、パッケージの種類を、市場の流行に合わせて選ぶことができる。

- 品質と安全性の保証 契約製造業者は通常、グミ・キャンディーの安全な消費を保証するために厳格な品質管理措置を維持する事業会社である。

業界の現状

ここ数年、グミキャンディの世界市場は拡大を続けている。統計によると、革新的なグミキャンディ、オーガニックで健康的なグミキャンディ、ユニークな形状の3Dグミキャンディが市場の主要な牽引役となっている。消費者の関心は味、デザイン、楽しさであるため、受託製造はブランドや小売業者の間でトレンドになっている。受託製造により、企業は市場の状況に素早く適応し、在庫リスクを軽減しながら、ホリデー、パーティー、プロモーションの需要に間に合うように新製品を発売することができる。

グミキャンディ受託製造業者を選ぶ5つの重要な要素

適切なグミキャンディ受託製造パートナーを選択することで、製品の品質と市場での競争力が保証される。以下の5つのポイントは、バイヤーが製造委託先を選択する際の重要な考慮事項である:

工場の資格と認証

安全なグミキャンディーを製造するためには、ISO、HACCP、FDA、または現地の食品安全認証のような法的認証や資格が必要である。適切な委託製造業者は通常、適切な認証を提供し、顧客に自信と国境を越えた販売と輸出の容易さを提供する。

生産能力

バイヤーは、工場が安定した生産能力を維持し、大量注文を納期内に処理できる高度な機械を備え、繁忙期や販促キャンペーン中に生産スケジュールを滞りなく動的に調整できることを確認すべきである。

原材料の安全性と品質管理

高品質のグミキャンディには、安全でトレーサビリティのある原材料が必要です。経験豊富な受託製造業者は、厳格な原料調達システム、品質検査工程、製造工程基準を策定し、グミキャンディの各バッチの味と色が一定であることを保証し、味と安全性に対する消費者の期待に応えます。

パッケージング能力

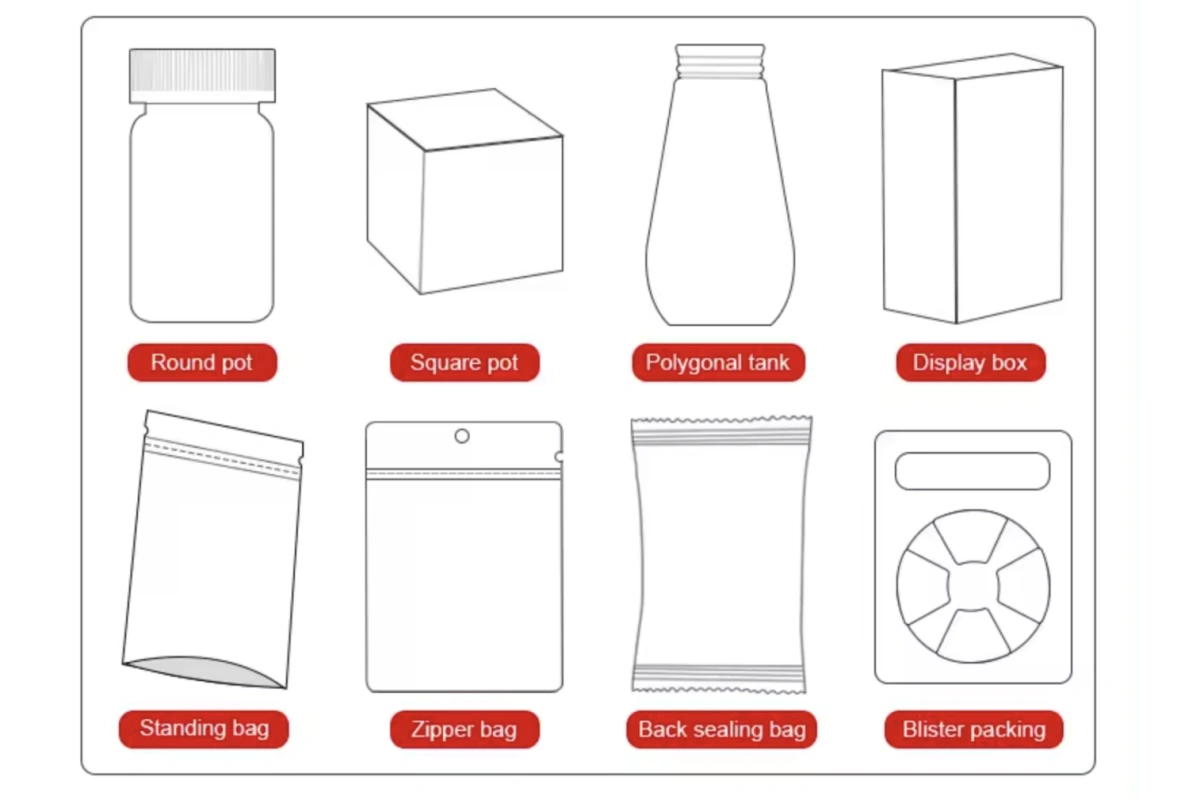

包装は、製品の外観や企業イメージに影響するだけでなく、輸送の安全性や賞味期限にも影響する。受託製造業者を選ぶ際には、製品の安全性や販売・出荷の完全性を確保するため、小分け包装、ギフトボックス、ホリデー用特別包装など、さまざまな包装に対応しているかどうかを問い合わせてみよう。

カスタマイズの柔軟性

厳しい競争市場において、差別化された製品は消費者を獲得するためのソリューションである。質の高い受託製造業者は、柔軟なカスタマイズ能力を提供できるはずであり、フレーバー、カラー、形状のカスタマイズ、OEM/ODMパッケージング・サービスを提供し、顧客が独自の製品ラインを作り、市場の競争力を高めるのを支援する。

グミキャンディの受託製造パートナーとしてLeChaoを選ぶ理由

グミキャンディ受託製造のプロフェッショナルとして、 レチャオ は豊富な経験と成熟した生産システムを誇り、製品の設計、生産から包装、出荷に至るまで、お客様にワンストップソリューションを提供しています。1991年に設立されたLeChaoは、グミキャンディの研究、開発、生産に焦点を当てた近代的なキャンディメーカーです。継続的な製品革新と厳格な品質管理により、高品質で風味豊かな卸売・バルクキャンディーを世界中のお客様に提供することをお約束します。

レチャオ には次のような利点がある:

強力な工場能力

LeChaoは、熟練した技術チームと近代的な工場工場と高度な機械を持っており、製品の品質と安定した供給を確保し、大量注文でもタイムリーな配信を保証します。

幅広い設計能力

お祭りやパーティー、お子様向けなど様々なニーズに対応し、立体的で楽しい形状のグミキャンディをご提案します。また、専門的な商品デザインのアドバイスも行っております。

バルク供給保証

当社の強固な生産能力と洗練されたサプライチェーン・マネジメントは、繁忙期や大量注文の際にも安定供給を保証し、在庫切れのリスクを最小限に抑えます。

魅力的な価格設定

工場直販のサプライヤーとして、LeChaoは競争力のある卸売価格を提供し、顧客は品質に妥協することなく利益を最大化することができます。

迅速で確実な配達

効率的な生産とロジスティクス・システムは、オンタイムでの製品納入を保証し、市場の需要や緊急注文への迅速な対応を可能にし、顧客の時間とコストを節約する。

グミキャンディ製造における一般的な問題と解決策

グミキャンディのOEM生産において、バイヤーは一般的に以下のような問題を経験する:

味の一貫性

問題だ: グミ菓子の味はバッチごとに異なることがあり、消費者の体験に影響を与える。

解決策 LeChaoは、標準的なレシピと同じ製造工程を使用し、厳格な品質管理を行うことで、各バッチで一貫した味を提供している。

色の一貫性

問題: グミキャンディの色は、原材料や製造工程の違いにより異なる場合があります。

解決策 高品質の食用色素を使用し、一貫した外観と視覚的アピールを保証するために、バッチ色差試験を実施している。

賞味期限管理

問題: グミキャンディは湿度や温度に影響されやすく、その結果、賞味期限が不安定になる。

解決策 科学的な処方、適切な湿度管理、効率的な包装・密封技術により、味と鮮度を確保しながら製品の賞味期限を延長している。

梱包の安全性

問題だ: 販売や出荷に影響を与える梱包の緩みや破損。

解決策 単体パッケージからギフトボックスまで対応できる安定した多層パッケージング・ソリューションを提供し、安全な出荷と容易な小売・流通を実現します。

カスタマイズされたニーズ

問題だ: バイヤーによって、形状、風味、包装の要件は異なる。

解決策 LeChaoは、包括的なOEM / ODMカスタマイズサービスを提供し、顧客の要件に応じて製品形態や生産計画を変更し、市場のニーズの変化に迅速に適応することができます。

概要

グミキャンディの受託製造は、ブランドや小売業者に迅速で柔軟、かつコスト効率の高い生産ソリューションを提供すると同時に、独創的で楽しく、高品質のキャンディを求める消費者の需要にも応えます。適切なOEMメーカーを選択することは、製品の品質とリードタイムを保証するだけでなく、差別化された製品を作り出し、市場競争力を高めることを可能にします。

グミ・キャンディの受託製造パートナーを選ぶ際には、製造業者の資格、製造能力、原材料の安全性、包装能力、カスタマイズの柔軟性などを考慮に入れるべきである。 レチャオ豊富な経験、洗練された設備、専門的な設計チーム、安定した供給能力で、お客様に開発から量産までのワンストップサービスを提供し、企業が市場で急速に拡大し、長期的なウィンウィンの関係を実現することを可能にします。