In candy manufacturing, consistent taste, appearance, and safety are fundamental to brand success. This article will take you through LeChao Candy‘s quality control system and how we ensure that every batch of candy is consistently reliable.

Why is Candy Consistency So Important?

Candy is more than just food for wholesalers and brands – it is an integral aspect of a brand’s identity. If no two batches of products taste, look, or feel the same, the consumer’s faith in that brand could be eroded.

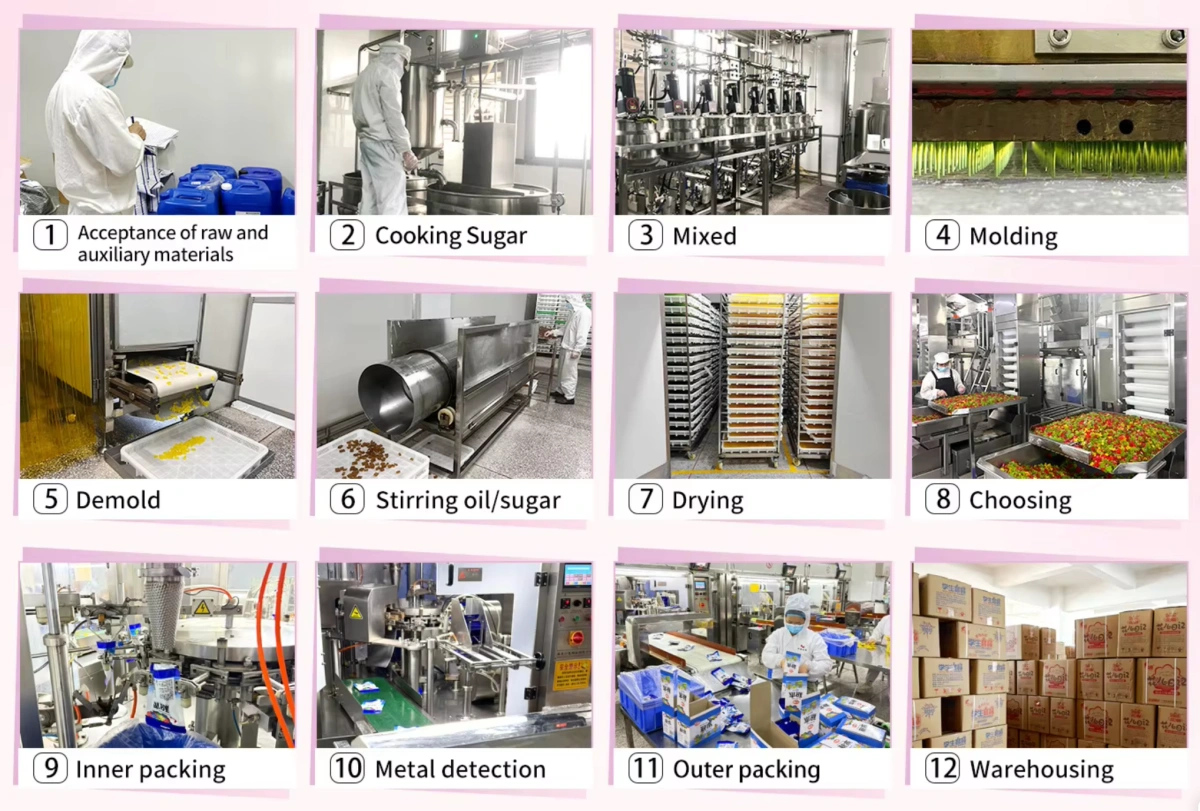

While LeChao recognizes the significance of this issue, we take precautions against product variation by implementing a standardized and reproducible method for maintaining quality assurance standards from beginning to end of our manufacturing process (raw material through shipment).

Overview of LeChao Candy Factory’s Quality Control System

Our quality control is not a single-stage inspection, but a closed-loop management system covering the entire production cycle, mainly including:

- Raw material quality control

- Formula and process standardization

- Production process monitoring

- Finished product testing and sample retention

- Batch traceability and continuous improvement

Starting from the Source: Strict Raw Material Management

Raw Material Selection and Supplier Evaluation

We only cooperate with audited raw material suppliers, strictly screening sugar, gelatin, pectin, flavors, and colorings to ensure their safety, stability, and compliance.

Raw Material Incoming Inspection

Each type of raw materials is physically verified on entry to the facility. This entry verification is to ensure all raw materials are consistent and will not create variability in the final product.

Standardized Formula and Process Control

Mature and Stable Formula System

LeChao has a mature formula library accumulated over many years. All formulas have been repeatedly tested and quantified to ensure high consistency in taste and structure between different batches.

Precise Control of Key Parameters

The production process has strict control over temperature, time, humidity and amount of water and mixing ratio of ingredients to eliminate production deviations resulting from human factors.

Real-time Quality Monitoring During Production

Multi-Node Quality Checks

Checkpoints throughout the production process allow for the identification and corrective adjustments of anomalies at an early stage so that problems cannot develop into an entire batch of defective products.

Standardized Molds and Forming Standards

We have over 500 types of candy molds, each having specific defined dimension and visual appearance specifications with which to accurately manufacture candy to a consistent and standard weight and shape.

Finished Product Testing and Batch Retention System

Finished Product Quality Testing

Every batch of candy undergoes inspection of appearance, taste, and basic physical and chemical indicators before leaving the factory, ensuring compliance with customer and market requirements.

Batch Retention and Traceability Management

We retain samples and records for each batch of product, ensuring quick traceability of production processes and raw material information when needed.

Continuous Improvement: Constantly Upgrading the Quality System

Quality control is not static.

LeChao continuously optimizes formulas and processes based on customer feedback, market trends, and new regulations, ensuring our products remain competitive

Choose LeChao Candy, Let Quality Become Your Brand Advantage

Founded in 1991, LeChao Candy is an experienced Soft Candy Manufacturer, specializing in the research and production of soft candies, licorice candies, jelly beans, marshmallows, and chocolate candies. With industry-leading customization capabilities, a rigorous quality control system, and mature global logistics services, we have become a long-term trusted partner for numerous brands.

If you are looking for a stable, reliable, and quality-conscious candy manufacturer, please contact LeChao Candy. Let’s work together to create candy products that consumers will repeatedly choose.