競争が激化する世界の菓子市場では、明確なブランドイメージを確立する必要性が高まっている。ホリデーシーズン限定のお菓子から、IPコラボやブランド商品まで、 カスタム・シェイプ・グミ は、棚で買い物客の目を引き、ブランドの認知度を高めることができる。ユニークな形状の カスタム・シェイプ・グミ また、カスタマイズされたグミの形状やフレーバーには大きな市場ポテンシャルがあるため、将来的には多くのブランドがグミの形状をカスタマイズした製品で差別化を図るだろう。

新しいブランド・ホルダーにとっては、"カスタム・グミの作り方?"処方設計、色調管理、食感、製造工程、食品安全基準、金型はカスタムグミの心臓部ではないが、それだけではない。

そこで、カスタムシェイプのグミの作り方についての包括的なガイドをご紹介します。 専門メーカー.このガイドブックは、プライベートブランド・キャンディを開発しようとしている小売業者や、新しいグミの開発に興味を持っている食品会社にとって、重要なステップや典型的なプロセス上の問題点とその解決策について、スピードアップを図る一助となることを目的としている。

製品要件を定義する:カスタムシェイプグミの出発点

成功するためには カスタム・シェイプ・グミカスタムグミは、単に形を変えるだけではありません。カスタムグミは単に形を変えるだけでなく、配合、味、テクスチャー、色、重さ、パッケージなど様々な側面が関係してきます。

形状要件を定義する

シェイピングはプロジェクト全体の出発点である。通常、以下のことを決定する必要がある:

- シェイピング・スタイル:漫画の形、動物、果物、お祝いのパターン、ブランドのロゴなど。

- 予想サイズ:グミの大きさは一般的に15~45mmで、それ以上の大きさにはより高い食感基準が要求される。

- 深さ:3Dモールドはより奥行きがあるが、より高価で、高級菓子ブランドに適している。

例えば:市販されている人気の動物型グミは、一般的に25~30mmの大きさで、かわいらしさと噛みごたえのある食感を兼ね備えています。ブランドロゴ入りグミを発売する場合は、ロゴのラインが金型変換に適しているかどうかを検討する必要があります。

フレーバーとテクスチャーの要件を定義する

味を決める際には、以下の質問に答える必要がある:

- クラシックなフルーツ味か、それともユニークな味か?

- 噛みごたえのあるグミ、ソフトなグミ、それともアメリカンスタイルのハードなグミ?

- 砂糖不使用、ゼラチン不使用、またはビーガン用のミルクが必要か(これらの要求は急速に高まっている)。

最も 人気のグミ・キャンディ・フレーバー 世界各地から集まった:

- ストロベリー

- ブルーベリー

- スイカ

- コーラ

- トロピカルフルーツ(マンゴー/パッションフルーツ)

ターゲット市場と規制

製品をEU、米国、南米、中東などに輸出する場合、異なる食品規制を満たす必要がある。例えば

- EUは特定の人工着色料を禁止している

- 米国FDAは、ゼラチンの供給源に厳しい条件を課している。

- 国によっては、ハラル/ハラール認証やヴィーガン認証の要件がある。

カスタム成形グミを作る前に、要件を定義することで、メーカーは既存の金型や配合を使用できるか、あるいは新しい金型やカスタマイズされた配合が必要かを迅速に評価することができる。

金型開発:カスタムシェイプグミ製造の核となる要素

金型は、この分野で最も重要な部分である。 カスタム・シェイプ・グミ を開発し、製品の視覚的な魅力と立体感を決定する。専門メーカーは通常、数百から数千のストック金型を持っている。 500以上のよく使われる金型果物、動物、祭り、ロゴなどの形状をカバーし、開発コストを大幅に削減します。

ストック金型の選択と新金型の開発

- ストックモールドを使う(無料または低価格)

予算が限られているエントリーレベルのブランドや小売業者に適しており、市場投入までの時間を短縮できる。

- 専用金型の開発(ディープ・ブランド・カスタマイゼーション)

通常、ブランド商品、IPとのコラボレーション、フェスティバルの限定商品などに適している。

開発サイクル:10~15日

コストデザインの複雑さによる(一般的にUSD 200-600)

金型材料と工程

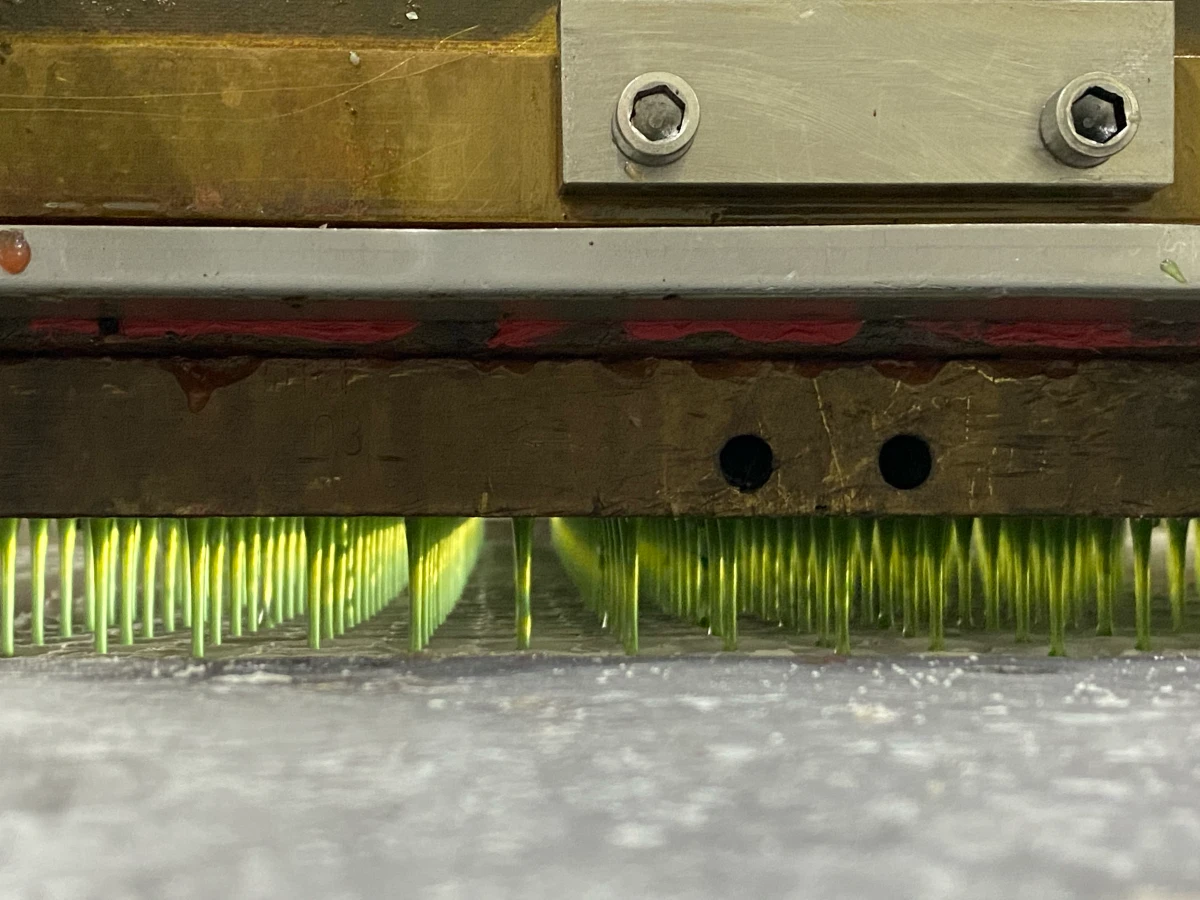

プロ用のグミキャンディ型は、通常、以下のものを使用する:

- 食品用シリコーン:少量試作に最適

- 金型(大量生産用):自動鋳造に適した耐高温性

金型設計の考慮点

- 線は細すぎないようにする:脱型時にグミキャンディが変形するのを避けるため。

- 適度な深さ:立体感と固化速度を両立させる。

- 鋭利な構造は避ける:壊れやすい

- ロゴや文字を拡大する読みやすさを確保するため

例有名人の知財を掛け合わせたブランドから発売された星型グミは、星の角の弧を深くすることで、丸みを帯びた形状になり、割れにくくなり、最終的な商品の仕上がりが良くなる。

配合開発:風味、食感、品質への鍵

フォーミュラこそ、その魂である。 カスタム・シェイプ・グミグミは、その弾力性、透明性、噛み応え、風味、保存性を決定する。例えば、欧米の消費者は硬くて弾力のあるグミを好むが、アジア市場では一般的に柔らかくて噛みごたえのある食感が好まれる。

3.1 4つの基本素材

コロイド(ゼラチン、ペクチン、カラギーナン)

- ゼラチングミは弾力がある。

- ペクチン・グミはよりフルーティーな風味で、ベジタリアンにも適している。

- カラギーナンのグミは柔らかく、子供用のグミに適しています。

甘味料(砂糖、グルコースシロップ、低糖質フォーミュラ)

酸味料(クエン酸、リンゴ酸)

天然/人工香料および着色料

フォーミュラ・コントロールのテクニック

- 透明度の調整:コロイドとシロップの比率は透明度に影響する。

- 弾力調整:ゼラチンの割合を増やすと、モチモチした食感が向上する。

- 甘酸っぱいバランス:酸味料の添加量は0.3%から1.2%の間でコントロールする。

特殊配合の例

- ビタミングミ(サプリメントタイプ):ビタミンの不活性化を避けるため、加熱温度をコントロールする必要がある。

- ゼラチンフリーのビーガングミ:ペクチンを使用し、セットシステムを強化する。- 機能性グミ:コラーゲン、プレバイオティクスなどを配合。

成功した処方は、通常、研究開発段階で少なくとも3〜5回の最適化テストが行われ、グミが温度や湿度が変化しても安定していることが確認される。

製造工程:シロップから製品までの全工程

特注グミの製造工程は主に、調理、高温混合、注入、型冷却、脱型、注油、乾燥、包装を含む。各工程は相互に関連しており、それぞれが完成品の品質に影響する。

シロップ料理

- 温度は125~135℃で安定させる必要がある。

- グミの食感を確保するためには、水分をコントロールしなければならない。

- 自動化された調理機器は、バッチの一貫性を保証する。

酸味と風味を加える

フレーバーと酸は通常、高温による風味の損失を避けるため、冷却段階で添加される。

注湯とセッティング

自動注入機は、熱いシロップを型に注入する。

- 精度誤差±0.1~0.2g以内

- セッティング時間 約6~12時間(レシピによる)

脱型と表面処理

脱型後、グミは成形される:

- 注油

- 乾燥(24~48時間)

- 選別(不良品の除去)

パッケージング

オプションあり:

- 個袋包装

- バルク包装

- カスタム印刷包装袋

パッケージはブランドイメージだけでなく、賞味期限や保存安定性にも影響する。

よくある問題と注意点カスタムシェイプグミ開発の成功率向上

を成功させるために カスタム・グミ・プロジェクトよくある問題を事前に回避することが重要なのだ。

金型と配合のミスマッチ

例えば、こうだ:

- ペクチン・グミは、エッジやコーナーを細かくしすぎると割れてしまうので適さない。

- 大きなロゴのグミは、変形を防ぐために「硬め」の配合が必要である。

色の違いと不安定さ

考えられる原因

- 顔料添加の不適切なタイミング

- 高温による色あせ

- 天然顔料の中には耐光性のないものもある。

型への固着と成形不良

解決策

- ゼラチンとペクチンの比率を調整する

- 粘着防止コーティングを追加するか、より適切な金型材料を使用する。

- セッティング効果を高めるために注湯温度を下げる。

物流と輸送の問題

輸出製品については

- 夏の長距離海上輸送には、溶融防止包装が必要である。

- 包装袋を厚くすれば、圧縮による変形を防ぐことができる。

高品質メーカー は、輸出国のさまざまな気候条件に応じて、対応する包装ソリューションを提供することができます。

結論

製造工程 カスタム・シェイプ・グミ は簡単そうに見えるかもしれないが、金型設計からレシピ開発、製造方法まで、すべての段階が最終製品の品質に影響する。そうでないブランドは キャンディ専門メーカー高品質のカスタムグミを製造するには、研究開発能力を持ち、自動化された工場を持っている、実績のあるメーカーと協力するのが最善の方法である。

お客様のご要望を明確に理解し、適切な金型を選択し、配合を改良し、製造フローに従うことで、お客様のブランドは、想像力豊かなデザインと素晴らしい味を持つ、価値の高いカスタムシェイプグミを簡単かつ迅速に製造することができます。

関連商品

ルチャオ・キャンディーズについて

1991年設立、 レッチョ・キャンディ をリードしている。 ソフトキャンディ・メーカーグミ、甘草キャンディー、グミビーンズ、マシュマロ、チョコレートキャンディーの研究開発と生産に特化しています。在庫は 500以上のキャンディ型 サポート OEM/ODMカスタマイズサービスデザイン開発、カスタマイズされたレシピ、迅速な見積もり、厳格な品質管理、グローバルな物流をブランドオーナーに提供しています。カスタムシェイプグミ、ホリデーキャンディ、ブランドコラボレーショングミなど、 レチャオ は、プロフェッショナルなワンストップ・カスタマイズ・ソリューションを提供しています。

よくあるご質問

1.カスタムグミのMOQはいくらですか?

形状や配合にもよるが、通常は200~500kg。既存の金型を使用することにより、MOQを大幅に削減することができる。

2.自分でデザインしたグミを送ることはできますか?

確かに。LeChaoでは、顧客が独自の2Dまたは3Dデザインを提供することができ、デザインがグミの形状に適していることを確認するのに役立つデザイン・ポインタを提供している。

3.ビーガン/ゼラチンフリーのグミは作れますか?

はい。私たちは、ビーガン、ハラル、その他の国際的な製剤のペクチンや植物ガムを、植物由来の溶液の形で用意しています。

4.カスタムグミの開発にはどのくらい時間がかかりますか?

既存の金型サンプルを使用する場合は、最短で7~10日、新しい金型を開発する場合は、通常10~15日を要する。